You are most welcome

From preliminary sketches to detailed drawings, from construction to realistic photographic animation – we will care for your project from start to finish.

Since 1993 Heinz Berlin’s engineering consultancy has been developing machines for the most diverse businesses. Along with our activities in the field of classical mechanical engineering we have specialised in the creation of concepts for new plants.

We will develop special solutions and solve problems for you with a variety of applications and in many different areas.

Just name your need – we’ll find a well-founded and economic answer for you.

Our consultancy will attend to you and your project from the very start. We begin with the conception, continue with construction and detailed representation and lead up to a realistic photographic visualisation and animation.

Thanks to our years of experience - we are the efficient and reliable partner you are looking for – especially if you want tailor made implementations in the field of mechanical engineering and plant.

Make use of our competence and ideas for your business.

You plan a successful business – we develop the necessary machines.

On the following pages we will introduce our consultancy and our services.Our lighthouse project: the Einstein Elevator

All about us

The proprietor, graduate engineer Heinz Berlin, has years of experience in the field of special machines and the development of specialist solutions.

Heinz Berlin’s engineering consultancy develops creative, practical and economical answers for the most diverse areas of mechanical engineering.

The basis of our successful work is exact and professional planning and customer focused examination of all relevant facts.

Implementing Ideas Successfully

Our work ethic regarding conception, planning and construction is defined by high quality and customer satisfaction. We achieve this through competence, experience and creativity. We develop concepts and special machines for the most diverse areas – all by ourselves. That is our strength – to the benefit of our customers.

Take a look for yourselves! On the following pages you can see customer references of some of our projects which are already up and running.

Capacity through tried and tested cooperation

If necessary we can increase our capacity as much as you like – through proven cooperation with competent partners. Naturally we will entirely supervise every order, so that the target oriented and punctual completion of our project is guaranteed.

3D-Fem – analysis of a welding assembly

Our strength are...

... plan and develop machines for the most diverse areas – in every size and context.

- Circulation testing bench

- Testing facility for conveyor belts

From small

Mechanisation for encoders, 20 000 u/min, dead weight 40gTo large

Circulation testing bench for conveyor belts, dead weight 107tFrom complex

Ply server for tyre building machines, over 70 motorized and 200 pneumatic drives in the lineTo fast

Automatic stacker for paper bags, 1200 pieces per minutes, piece division is integratedOur Experience

Here you can see a selection of our personally supervised and implemented projects. We design machines for the production of...

Tyres

- Tyre-winding machine

- Belt layer feeder

- Carcass layer feeder

- Hard shoulder feeder

- Tread feeder

- Clamping drums

- Winding machines

- Carcass transport

Air springs

- Air springs assembly machines

- Layer feeder

- Hemming presses

- Test basin

- Roll on devices

- Vulcanisation plants

Research

- Einstein Elevator

- Traction resistance test stands

- Drill simulators

- Stone chambers

Conveyor belts

- Winding and unwinding units

- Rope tensioning stations

- Vulcanisation presses

Paper products

- Stacking machine for bags with side folds

- Paper drum winding machine

Tooth and V-belt

- Cutting and feeding table

- Automatic feeding system

- Cuff handling

- Lay-up machine for v-ribbed belts

- Cutting units

- Marking device

- Material transport cassettes

- Vulcanisation press

Batteries

- Plate cutting machine

- Forklift

- Paper stand

- Processor

We have further experience in the following areas

- Product development

- Testing machines

- Presses up to 7 MN

- Conveyor technology

- Damage analysis

- Welding technology

- Tool making machines

- Glass fabrication

- Toolmaking

- Theatre and stage production

- Plastic processing

- Rail vehicle technology

- Drilling technology

- Biscuit ovens

Referenzen

- aha Abfallwirtschaft Region Hannover

- Bahlsen GmbH, Barsinghausen

- Baker Hughes, Celle

- Continental AG, Hannover

- ContiTech Antriebssysteme, Hannover

- ContiTech Luftfedersysteme, Hannover

- ContiTech Transportbandsysteme, Northeim

- D.I.E Metallwerkstatt, Alfeld

- Eilhauer Maschinenbau, Langenhagen

- FH Bielefeld

- Forbo Siegling GmbH, Hannover

- Garant Maschinen, Lengerich

- HS Bochum

- Intorq, Aerzen

- Laier Bühnentechnik GmbH, Hannover

- Leibniz Universität, Hannover

- Lenze, Hameln

- Schlüter Maschinenfabrik, Neustadt a. Rbg.

- TU Clausthal

- ÜSTRA, Hannover

- VB Autobatterie Gmbh & Co KGaA, Hannover

- Wendt Maschinenbau, Georgsmarienhütte

Projects

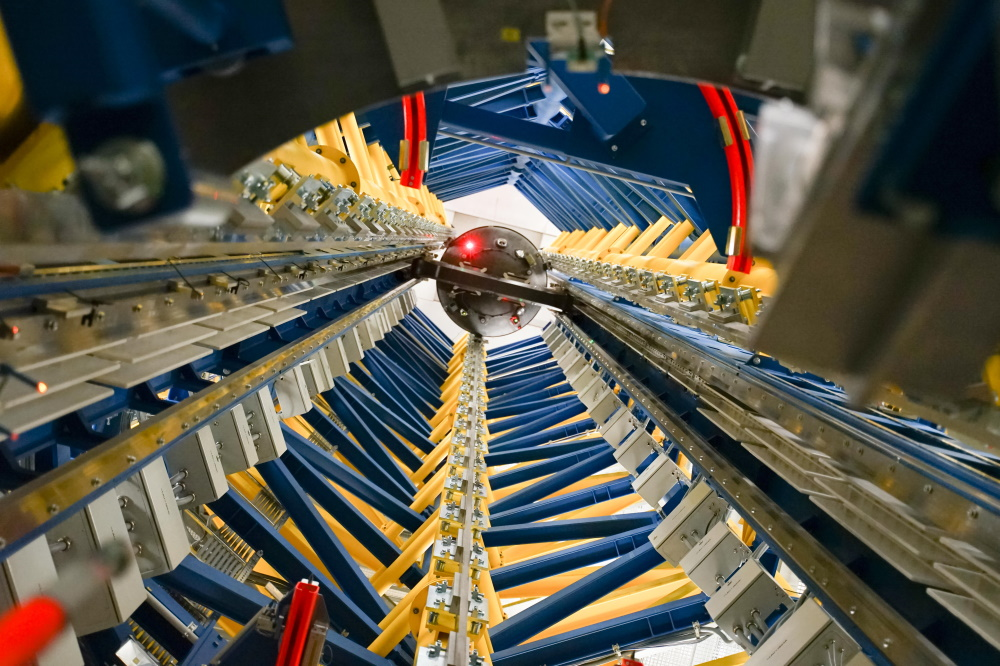

Einstein-Elevator

The one and only Einstein Elevator

Our services:

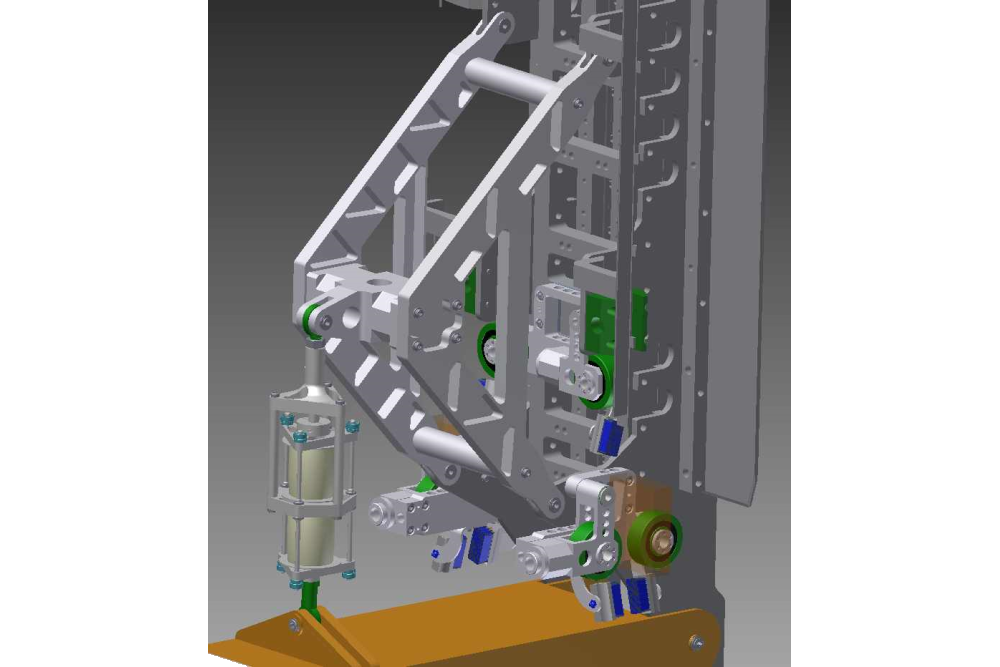

- Basic concepts of mechanical construction

- Specification for foundation and building design

- Concepts for all mechanical components

- Static and dynamic design of mechanical components

- Detailed constructions

- Supervision of construction and implementation

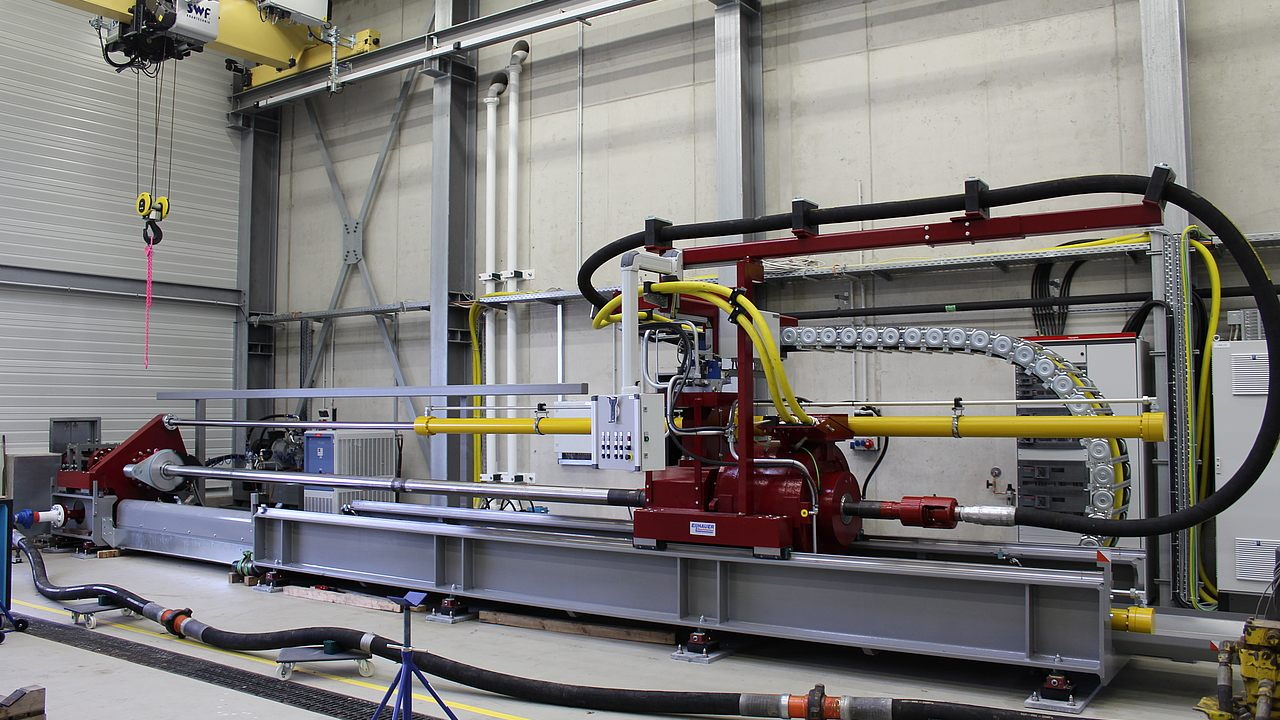

35kN Circulation testing bench

The world’s biggest circulation testing bench for conveyor belts, dead weight 107t, total force 7MN.

Here too, we guide and support you from the first concept to the sucessful implementation!

Drilling simulator

One last example – which shows that we support you from concept, to the mechanical, electrical and hydraulic interpretation, to the final implementation.

These research projects can be openly publicized………

Our industrial projects are just as exciting………

Contact

Make an appointment! We look forward to hearing from you.